How conveyor chains are made

Conveyor chains are essential components used in various industries for material handling applications. These chains are typically made using specialized manufacturing processes. Here’s an overview of how conveyor chains are typically produced:

Material Selection: Conveyor chains are often made from high-strength steel or other durable materials, depending on the specific application requirements.

Raw Material Processing: The selected material is processed into the appropriate form. For steel, this involves melting the raw material in a furnace and then casting it into the desired shape, such as billets or bars.

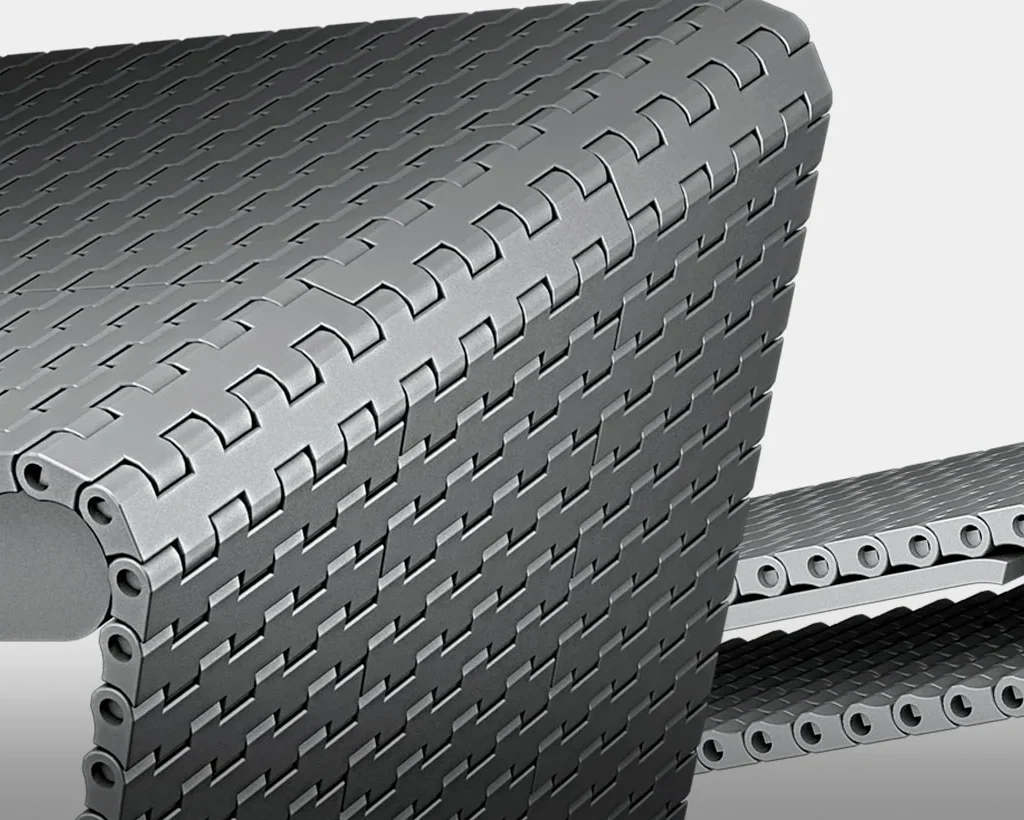

Forming and Shaping: The formed material is then heated to a specific temperature to make it more malleable. Different manufacturing methods can be employed, such as forging, stamping, or rolling, to shape the material into individual chain links.

Machining: Once the basic shape of the links is achieved, they undergo machining processes to refine the dimensions and achieve precise tolerances. This might involve drilling holes, cutting threads, or grinding to ensure the links meet the required specifications.

Heat Treatment: Heat treatment is crucial to enhance the strength, hardness, and durability of the conveyor chain. The links are heat-treated by processes such as quenching and tempering, which involves heating the metal to a specific temperature and then rapidly cooling it to achieve the desired properties.

Assembly: After individual links are manufactured and heat-treated, they are assembled into a chain. This involves connecting the links using pins or rivets to create the continuous loop that forms the conveyor chain.

Surface Finishing: Surface finishing processes like polishing, coating, or plating might be applied to improve the chain’s resistance to corrosion, wear, or to provide specific surface characteristics.

Quality Control: Throughout the manufacturing process, quality checks are performed to ensure the conveyor chain meets the required standards and specifications. These checks involve measurements, inspections, and testing to verify the chain’s strength, dimensions, and overall quality.

Packaging and Shipping: Once the conveyor chains pass quality control inspections, they are packaged appropriately and shipped to customers or distributors for use in various industries like manufacturing, automotive, food processing, and more.

It’s important to note that the specific manufacturing process can vary based on the type of conveyor chain being produced and the industry standards or requirements. Advanced automation and precision machinery are often employed in modern conveyor chain manufacturing to ensure high-quality and consistent production.